-

This product has been discontinued by the manufacturer however parts may still be available

Click HERE to view the replacement item

Please call 909-614-4522 to speak with one of our trained product specialists

-

Brand : ACU-RITE

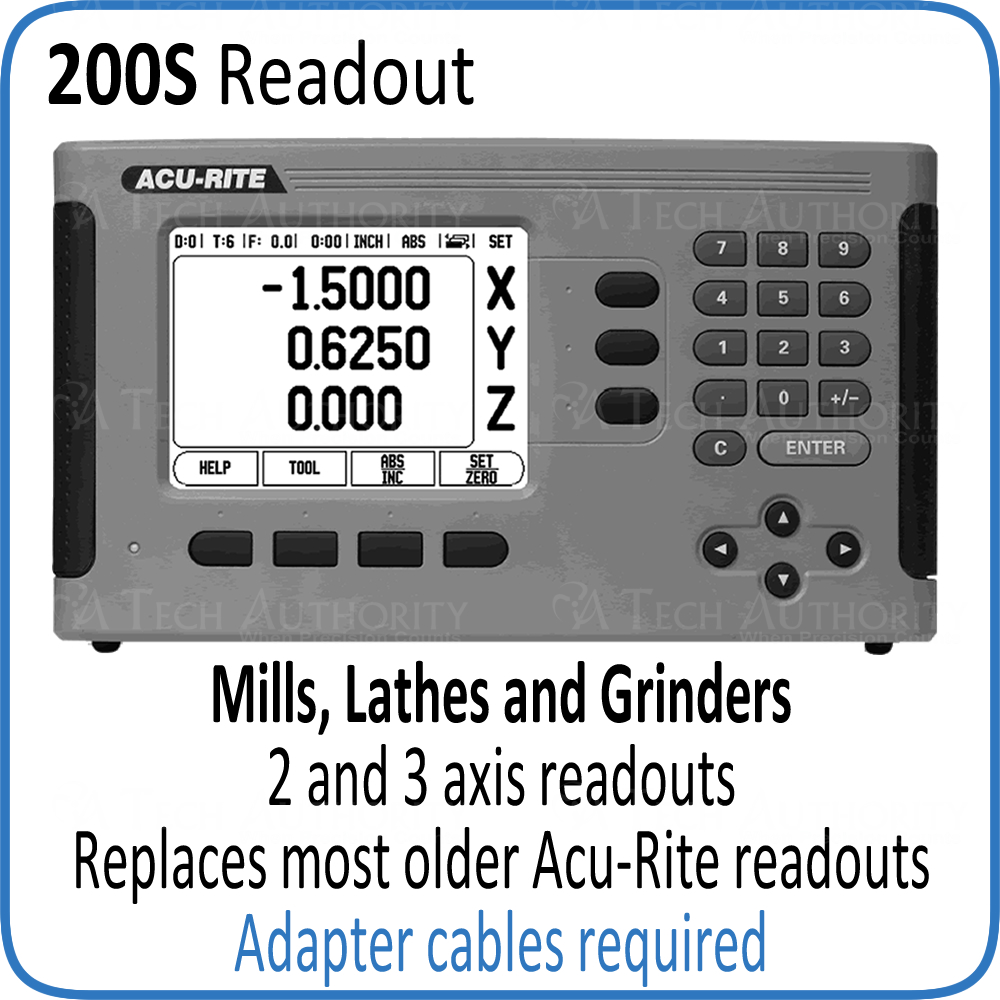

200S

-

The ACU-RITE 200S features exclusive LCD display screen technology and versatile software to accommodate milling, turning or grinding applications.

- Request A Quote

Description

The ACU-RITE 200S is a full-featured readout which comes in 2 and 3 axis versions, both feature a 5.7 LCD display, as well as the following features...

General Functions

- Near-zero warning

- Help function

- 16 tool offsets / diameter

- Preset and zero reset

- 4 function calculator / Trig calculator

- Instant inch/mm conversion

Mill Specific Functions

- Bolthole pattern calculations with graphics (full and partial circles)

- Centerline calculation enables you to establish workpiece zero and

- Edge finder input

Turning / Lathe Specific Functions

- Lock axis feature

- Instant radius / diameter conversion

- Taper calculator

Related Products

SENC 150 by Acu-Rite By:Acu-Rite

The ACU-RITE SENC 150 precision glass scale incorporates the latest innovation in roller bearing technology for reduced backlash and greater scale travel life....